The Indonesian Ministry of Industry highlights the vital role of silica downstreaming in developing a robust semiconductor industry, with potential significant benefits for national economic growth and job creation.

According to Ignatius Warsito, the Ministry’s expert staff in strengthening domestic industrial capabilities, enhancing the upstream and midstream sectors by transforming silica into Solar Grade Silicon (SGS) and Electronic Grade Silicon (EGS) wafers is essential. Silicon wafers serve as foundational materials for semiconductor and solar cell industries, yet the capability to process silica into solar-grade silicon wafers is currently unavailable in Indonesia.

This initiative aims to support the self-sufficiency of the domestic photovoltaic (PV) module and semiconductor industries. To achieve this, the ministry plans to develop a comprehensive silicon wafer industry roadmap and an industrial tree structure, starting from drafting the Silica Downstreaming Action Plan for 2023, with a roadmap scheduled from 2025 to 2035. The finalization of the roadmap is set to begin in 2024, followed by establishing related industrial regulations.

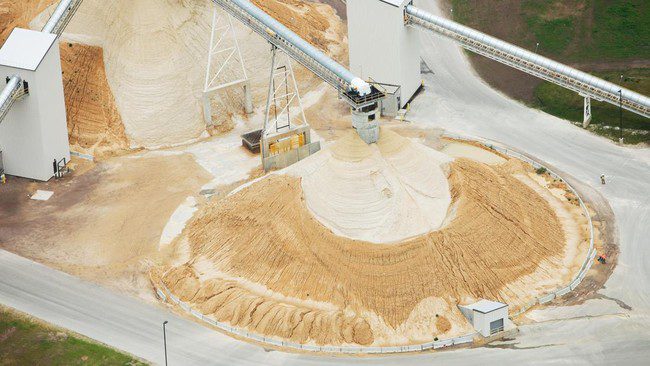

Wiwik Pudjiastuti, Director of Cement, Ceramics, and Non-Metallic Mineral Processing Industries at the Ministry, mentioned that as of now, there are 21 silica sand processing companies with an installed capacity of 738,536 tons per year. In 2022, nine of these companies produced a total of 404,755 tons, achieving a 68.48% utilization rate. The primary products in demand include silica sand, silica flour, and resin-coated sand.

Regarding potential mining locations, notable silica sand mines are found in Bangka Belitung, Central Kalimantan, and West Kalimantan, alongside possible sites elsewhere. Quartzite resources, predominantly located in Aceh, are estimated at 297 million tons.

From a raw materials perspective for the PV and semiconductor industries, 2022 statistics from the Central Bureau of Statistics (BPS) show potential for significant import substitution values: $17.7 million for Silicon Wafers, $120 million for semiconductor products, $6.2 million for unassembled solar cells, and $65.9 million for assembled solar cells.

Wiwik emphasized that local preparation of these materials could unlock substantial potential for Indonesia, thus capturing substantial opportunities for importing substitute silica-derived products for the PV and semiconductor industries.